July 2025

After several iterations on the TE-cooled laser diode mount, I have finally arrived at a performant, reliable, compact, easy-to-build, and relatively low-cost design. The present design can reliably cool 5.6mm TO-packaged diodes to -20C with sub-mK temperature stability, without condensation, and without the influence of atmospheric variations on the diode characteristics. When driven by Sinara Kirdy, even with a dirt-cheap laser diode installed (think recycled CD/DVD writer diode), it can keep the generated optical frequency within Doppler-broadened (˜GHz) spectral lines for weeks, relying on current, temperature, and vacuum stability alone. Even higher optical frequency stability, likely suitable for Doppler cooling, can be achieved inexpensively by using spectroscopic feedback and Soundlocker on top.

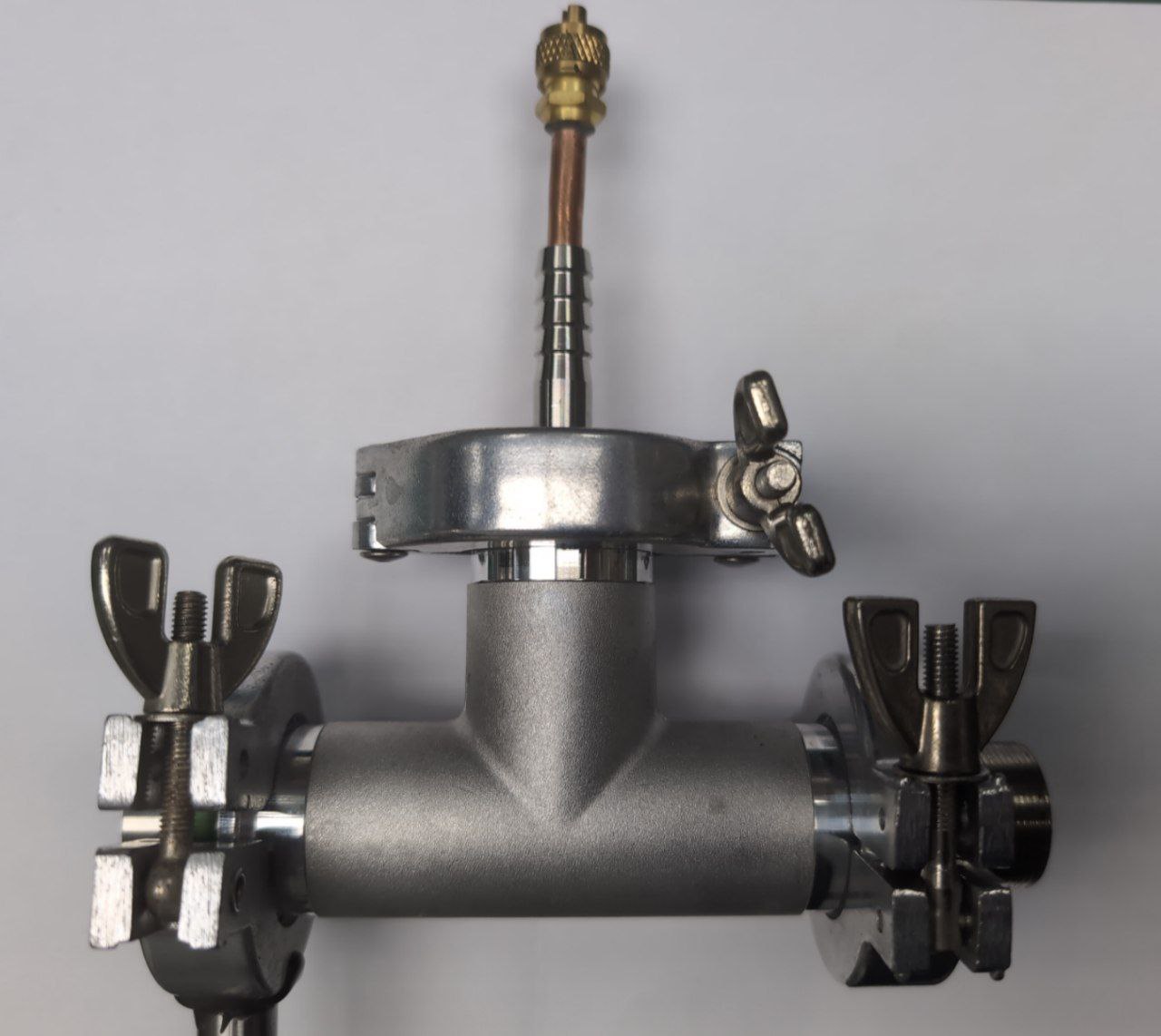

The driving idea is to use standard or off-the-shelf vacuum components to eliminate the difficult problems associated with vacuum sealing. The KF25 tee is the smallest standard vacuum part with three ports (electrical feedthrough, optical window, pumping) that would comfortably fit a 5.6mm diode and its collimator, a thermistor, and a TEC. So it was chosen as the vacuum chamber for this design.

The main challenge with this approach is getting rid of the heat produced by thermoelectric cooling.

The first issue is that most KF25 tees are made of stainless steel, which has poor thermal conductivity. But a number of vacuum suppliers have special ones made of aluminum, and Highlight Tech Corp sells them at much more reasonable prices than many others.

The second issue is efficiently conducting the heat from the flat surface of the TEC to the circular surface of the KF25 tee. A custom CNC-machined heat spreader made of copper is used for this purpose. It can be attached to the KF25 tee using thermal epoxy, but the issue with this method is that the mounting is permanent which makes the laser difficult or impossible to repair or modify. Good results can be obtained by using Apiezon Wax W into which copper powder with a 5-micron particle diameter has been mixed, in concentrations as high as practically possible (too much powder will make the wax brittle and non-sticky). Use a mortar and pestle on a temperature-controlled hot plate to prepare the mix. The mounting is then reversible by simply heating the KF25 tee with a hot air gun or blowtorch to melt the wax. Do not skip the copper powder as it does make a huge difference in thermal conductivity and achievable diode temperatures! The inspiration for this trick came from the Tech Ingredients video "Make Our Best Thermal Paste... YOURSELF!" - and this channel has plenty of other helpful advice regarding thermal interfaces.

The heat spreader has a slot to fit a CP20147H TEC, at an angle that diverts the Fresnel reflection from the vacuum window away from the diode. The TEC is mounted using 8329TFS thermal epoxy on both sides. On the other side is another custom CNC-machined copper part which receives the laser diode (soldered with indium-tin eutectic alloy for maximal thermal conductivity), the collimation lens (the M9x0.5 thread is the de-facto standard for inexpensive lenses from China, and some are of very good quality), and the NTC thermistor also mounted with 8329TFS epoxy. The hole next to the laser diode is for venting the space between the diode and the collimation lens, and care should be taken to avoid blocking it with the InSn solder. It may help to carefully clean the case of the laser diode and pre-tin both surfaces with the InSn solder before assembly, in particular if the laser diode is a recycled one or the copper mount shows signs of oxidation.

The pump-down port and vacuum valve is built by inserting a refrigeration access valve into a KF25 10mm hose barb adapter, and sealing it with epoxy glue. Using Apiezon wax there is not recommended since it is too brittle and breaks easily when the pumping hose is connected. After heat curing in air, Araldite 2014-2 produces sufficiently low outgassing for the modest vacuum levels required by this project; more specialized (and potentially expensive and hard to buy) vacuum epoxies are not necessary. The key to obtaining a vacuum-tight seal is to make a blob of epoxy on the vacuum side with all surfaces wetted properly. See here for a picture of the result (ugly but works). For creating the vacuum, an inexpensive oil-sealed rotary vane pump such as the 2XZ-0.5 is sufficient.

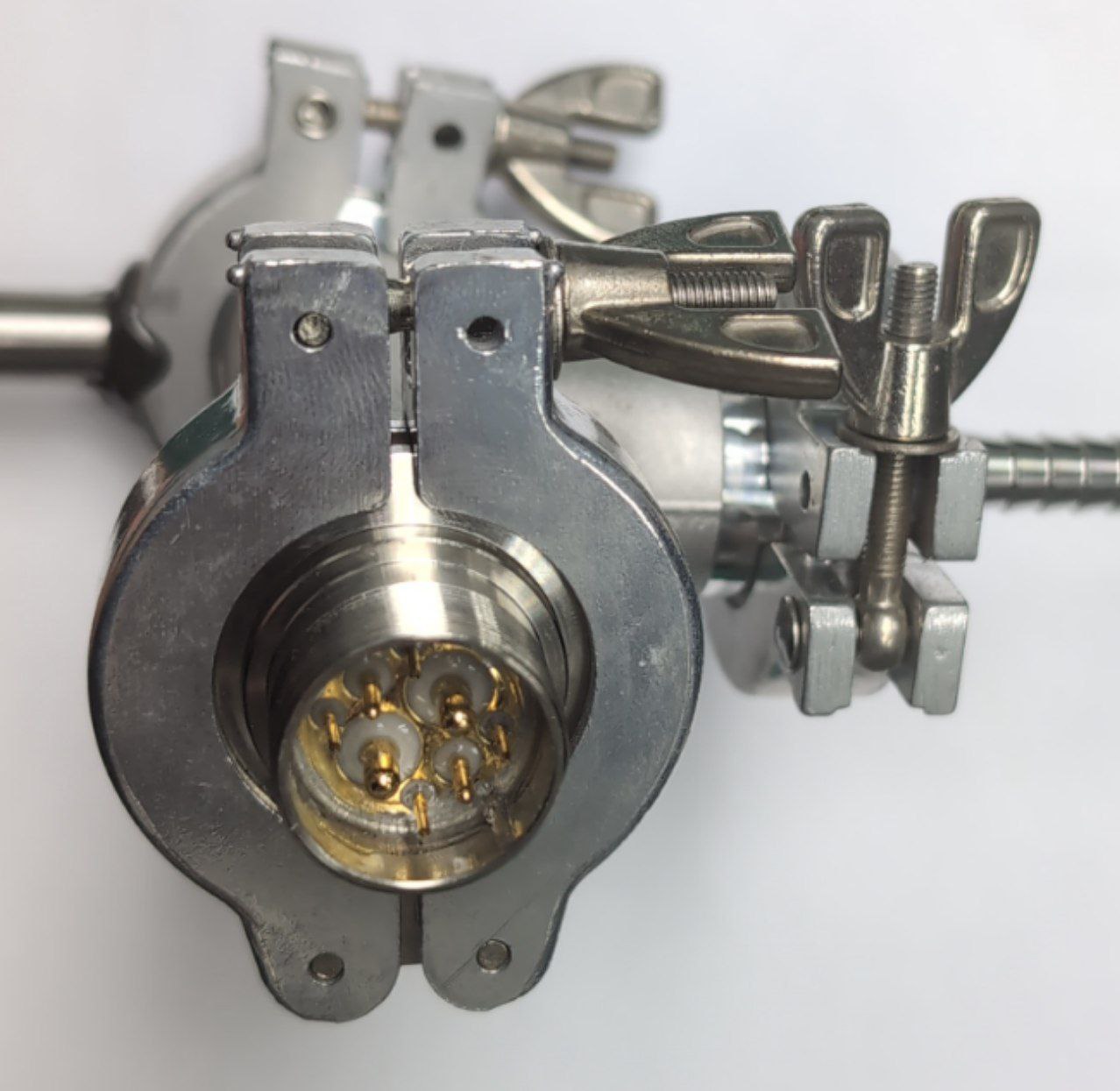

The electrical feedthrough is a low-cost KF25 aviation connector model, made by several Chinese suppliers. Suitable ones have 6 or 8 pins; the 8-pin version has more balanced conductor sizes and the extra two pins allow for the connection of a miniature Pirani gauge (could be a small incandescent light bulb that has been cut open) to monitor the vacuum level, particularly in case you are using this mount with an expensive laser diode that you cannot afford getting condensation on.

| Part | Quantity | Example source |

|---|---|---|

| KF25 aluminum tee | 1 | Highlight Tech Corp, P/N: KF25TEAL |

| KF25 window | 1 | Highlight Tech Corp, P/N: KF25VW |

| KF25 10mm hose barb adapter | 1 | Aliexpress |

| Refrigeration access valve | 1 | Aliexpress |

| Araldite 2014-2 | RS 164-9063 | |

| KF25 6-pin or 8-pin aviation connector feedthrough | 1 | Aliexpress |

| KF25 gasket with centring ring | 3 | Aliexpress or Highlight Tech Corp |

| KF25 clamp | 3 | Aliexpress or Highlight Tech Corp |

| TEC Same Sky CP20147H | 1 | DigiKey 102-4042-ND |

| NTC thermistor EPCOS B57861S0103F040 | 1 | DigiKey 495-2142-ND |

| Collimation lens M8P0508F4762-S-H | 1 | Aliexpress |

| CNC-machined LD/NTC/collimation block | 1 | PCBWay |

| Thermal epoxy MG Chemicals 8329TFS | DigiKey 473-1364-ND | |

| InSn solder | DigiKey SMDIN52SN48-ND | |

| CNC-machined heat spreader | 1 | PCBWay |

| Apiezon Wax W | Che Scientific Co. | |

| Copper powder 5 micron | Taobao |